|

Tuesday, June 19, 2012

LOWEST PRICE DOES NOT MEAN LOWEST COSTLOWEST COST CARTONER PURCHASE PRICE DOES NOT MEAN LOWEST OVERALL COST!

CONSIDER

THE TOTAL COST TO PACKAGE THE PRODUCT!

While the purchase cost of the machine is of course

important, consider the following total cost of ownership and total cost to package the product factors

when reviewing pricing and cartoning machine specifications for your project The lowest

priced cartoner usually DOES NOT produce the lowest cost per unit to package the product.

A major consideration of the cartoner purchase is of course cost.

But the real cost

is the total cost to package the product.

These components include

the costs associated with the cartoner long after the purchase.

Considerations in total overall costs

to package the product include:

UPTIME RELIABILITY- The machine should run day in and day

out with minimal if any issues.

PRODUCTION OUTPUT- Along with consistent reliability,

the cartoner should produce high quality

product at rated speeds with minimal rejects.

MINIMAL MAINTENANCE AND OPERATOR ADJUSTMENTS- Cartoners should run with high

reliability

and produce product without tweaking, adjusting or banging with a hammer.

SPEED OR CARTONS

PER MINUTE-The higher costs associated with quality components and

robust design considerations

pays off big time, resulting in increased speeds and thus increased output per shift, per week, per month, etc.

DURABILITY-Make sure the cartoner is robust and will stand the test of time. Cartoner reliability and longevity

should be measured in decades, not months or years.

For further information and outstanding cartoning solutions

contact us at: Telephone: 224 628 4867 Email: info@pmpmachine.com Website:www.pmpmachine.com

Friday, May 4, 2012

CARTONING MACHINERY PURCHASING TIPS- LESS IS MORE

When purchasing cartoning machinery for your plant, the typical sales talking points may not provide the best

advice for a significant amount of cartoning applications. For outstanding performance and reliability

for cartoning machinery, often times less is more.

A vertical cartoner as an example producing 100 cartons per

minute provides no more or less production if the cartoner is equipped with a more expensive servo motor or a simple Baldor

motor. The design (good or bad) and quality of components and workmanship play a much more significant role.

I once read the following advice from a purchaser of cartoning machinery:

1. Avoid Proprietary Controls-

The machine should be completely transparent without any black boxes. There is nothing worse than a black box on packaging

machinery.

2. Make the machine as simple as possible- Could your most recent hire operate the machine

or does the operator need an electrical engineering degree to toggle through a complicated yet unnecessary array

of screens.?

3. By keeping the cartoner simple you reduce the number and cost of spare parts. Machinery

with less parts and readily available purchased parts significantly reduce the cost to operate as opposed to overly

complicated cartoners with proprietary replacement parts that provide one heck of a spare parts business for the machinery

supplier. Good for them, not so good for you.

3. The Cartoner Must Be Reliable and Durable- You

should be measuring reliability in decades not measured in months or years. Make sure the cartoner is robust to perform

day in and day out for years.

Packaging Machinery Products has decades of cartoning machinery experience

and can assist you with your new or used cartoner purchase.

Fri, May 4, 2012 | link

Tuesday, February 28, 2012

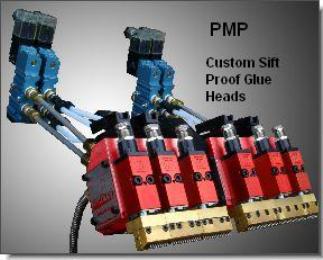

SIFT PROOF CARTON GLUING ELIMINATES THE COST OF BAG IN BOX.An often overlooked cost advantage in carton filling is the sift proof carton glue option. The first thought when

cartoning powders or granular product is to use the bag in box method. This of course works quite well but adds the

cost of filling and producing the bag that will be used for the product and then requires loading the bag into the carton.

Along with the additional cost of the bag material, packagers should consider the cost of operating and maintaining the bagger

equipment. An excellent option to the traditional bag in box filling method is to eliminate the bag completely along

with all of the related costs and direct fill into the carton with a sift proof carton sealing configuration. Consider

the potential cost savings that can be realized by employing the sift proof carton sealing option along with direct filling

into the carton. Eliminates the purchase and maintenance costs of the bagger. Eliminates the costs to purchase

bag material especially during the spikes in the costs of petroleum based products. Eliminates the costs

required to load the bag into the carton. Direct filling into the carton via a integrated volumetric filler, auger or scale

unit eliminates the manual loading of bags or the often complicated auto push loaders that contain many parts and jam areas. PMP Machine

does caution the purchaser to consider using only experienced cartoning machinery suppliers when opting for the sift proof

carton option since the application requires custom designed glue heads to apply the proper glue bean pattern to the cartons

to insure a tight seal. Here is a typical PMP sift proof head that will be custom designed and built for your application.

Contact PMP Machine to further discuss your Sift Proof Cartoning Requirements.

Wednesday, December 14, 2011

AUTOMATIC CARTON ERECTORPMP is excited to announce the availability of our new Auto Bottom Carton Erector Model AB1400! This auto bottom

carton erector automatically removes carton from magazine, forms and locks the carton. The auto carton erector can run

independently or be integrated with downstream filling equipment. You can view the new carton erector on the PMP website

page.

Sunday, July 31, 2011

Purchasing a Used CartonerWith budget's still tight, purchasers must often decide between purchasing a new cartoner or a used cartoner. Purchasing

a used cartoner often saves both time and money. Success with the purchase of a used cartoner however, will often depend on

the experience, knowledge and honesty of the seller involved. PMP as an example only provides cartoners and maintains

an excellent track record of providing used cartoning solutions to our customers. Make sure your supplier can provide after

sale support such as spare parts, on site service if required, and can answer your cartoning questions. We have also

had the unfortunate experience of "rebuilding the rebuild" provided by other suppliers that our customers turned

over to us to get it right. Please choose a cartoning supplier wisely when purchasing a used cartoner and the result

will be a trouble free experience both during and most importantly after the sale.

|